Self-Dumping Bins: Your Key to Efficient Material Disposal

In industrial and commercial sectors, managing waste and materials efficiently is essential. Self-dumping bins offer a streamlined solution for handling and disposing of various materials. Also known as self-dumping hoppers or forklift hoppers, these bins improve safety, efficiency, and productivity in workplaces where material handling is a daily task. This article explores the advantages, types, and uses of self-dumping bins, focusing on those used with cranes and forklifts.

What Are Self-Dumping Bins?

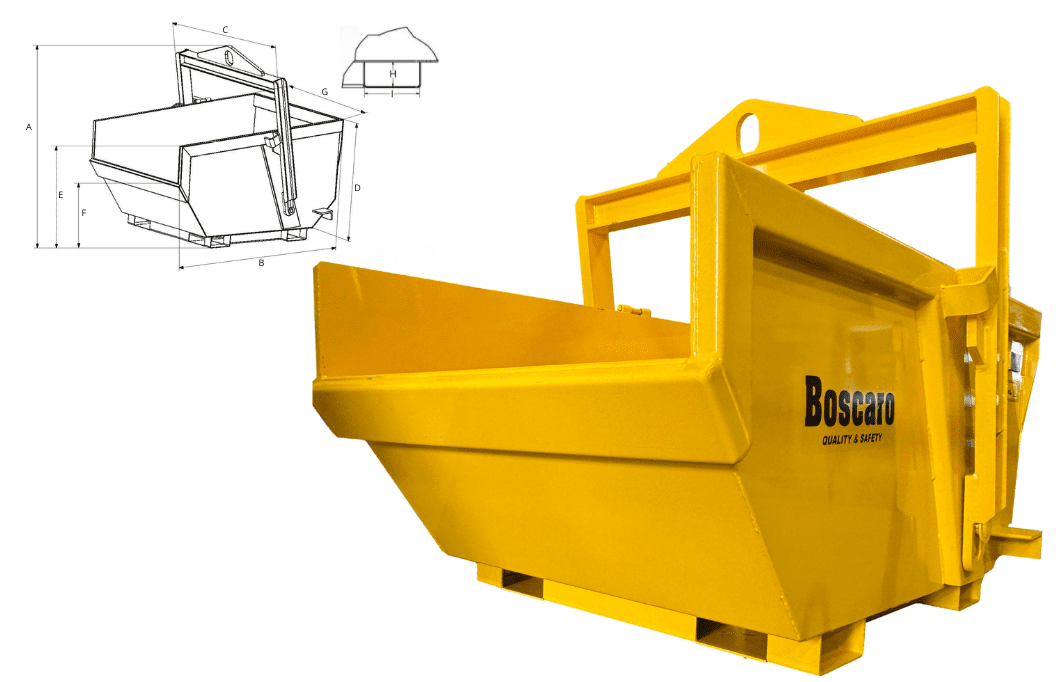

Self-dumping bins are specialized containers designed for easy, efficient material disposal. They automatically tip and empty their contents when a latch is released, then return to an upright position for refilling. This automated process reduces the need for manual handling, boosting both safety and efficiency on the job.

How Do Self-Dumping Bins Work?

Self-dumping bins are simple to use but incredibly effective. Here’s how they work:

- Loading: Materials are loaded into the bin by hand or machinery, depending on the type and amount. These bins can hold various materials, from construction debris to recyclables.

- Transporting: Once filled, the bin is lifted by a forklift or crane. Forklift-compatible bins have fork pockets that securely fit the tines, ensuring safe transport. Crane-compatible bins have lifting lugs that allow easy movement to the disposal site.

- Dumping: At the disposal site, the operator releases the latch, causing the bin to tilt forward and dump the contents quickly. The design ensures all materials are emptied without needing manual intervention.

- Returning: After dumping, the bin returns to its upright position using gravity and a counterbalance mechanism. It’s ready for loading again.

Benefits of Using Self-Dumping Bins

Self-dumping bins offer many advantages, making them a go-to for efficient waste disposal and material handling:

- Boosted Efficiency: These bins simplify material handling. Instead of manually loading and unloading waste, workers use machinery, saving time and reducing labor costs. This efficiency allows them to focus on other tasks, improving overall productivity.

- Increased Safety: Self-dumping bins minimize manual lifting, reducing the risk of injury. Workers no longer need to handle heavy or hazardous materials directly. Using forklifts or cranes further increases safety.

- Versatility: Self-dumping bins can handle various materials, from scrap metal and construction debris to recyclables and general waste. They are useful in many industries, including construction, manufacturing, landscaping, and waste management.

- Durability: Built from robust materials like steel, self-dumping bins can withstand harsh environments and daily use. Their durability reduces the need for frequent replacements, offering long-term savings.

Types of Self-Dumping Bins

There are various types of self-dumping bins, each designed for specific industrial needs. Understanding the differences helps you choose the right bin for your operations:

- Forklift Dump Bins: These bins are made for forklifts. They feature fork pockets for secure attachment, making lifting and dumping quick and efficient. They’re common in warehouses, distribution centers, and manufacturing plants.

- Crane Dump Bins: These bins, also known as crane dumpsters, are equipped with lifting lugs for use with cranes. Perfect for heavy-duty tasks, they handle larger loads and are ideal for construction sites and industrial operations.

- Industrial Series Bins: Made from high-gauge steel, these bins are built for heavy-duty use. They handle large volumes of material and withstand the demands of tough industrial environments, such as manufacturing plants and warehouses.

- Commercial Series Bins: These smaller, maneuverable bins are designed for lighter, more frequent use. They are ideal for commercial facilities like retail stores and smaller warehouses.

- Specialty Bins: Specialty bins are designed for unique applications, such as handling liquid waste or hazardous materials. Some have side-release mechanisms for easier unloading.

Using Self-Dumping Bins with Cranes and Forklifts

When using self-dumping bins with cranes, it’s important to ensure they’re securely attached, and the crane has sufficient lifting capacity. Crane bins handle larger, heavier loads, making them perfect for construction sites that generate a lot of debris.

Forklift bins are commonly used in warehouses and manufacturing facilities. They attach easily via fork pockets, making them quick to move and dump. Forklift bins are ideal for handling smaller volumes of waste, such as scrap metal, wood shavings, and packaging materials.

Industrial Applications of Self-Dumping Bins

Self-dumping bins play a vital role in various industrial settings. Here are some common applications:

- Construction Sites: These bins quickly collect and dispose of construction debris, scrap metal, and packaging materials, helping keep the site clean and safe.

- Manufacturing Plants: Self-dumping bins handle scrap materials, by-products, and packaging waste, streamlining disposal and boosting productivity.

- Warehouses: These bins help manage packaging materials and damaged goods, reducing clutter and improving safety.

- Recycling Facilities: Self-dumping bins make it easy to sort and transport recyclables, improving the efficiency of recycling processes.

- Landscaping and Agriculture: They collect and dispose of organic waste, such as grass clippings and leaves, reducing labor time and improving cleanliness.

- Mining and Heavy Industry: These bins are built to handle heavy, abrasive materials like rocks and ores, making them ideal for tough industrial environments.

Choosing the Right Self-Dumping Bin

Selecting the right self-dumping bin is essential for efficient waste management. Here are a few factors to consider:

- Material Type: Heavy materials like scrap metal require robust steel bins, while lighter materials like paper or plastic can use lighter commercial bins.

- Waste Volume: High-volume waste requires larger bins, which means fewer trips to the disposal site. Smaller bins work well for lighter loads.

- Equipment Compatibility: Ensure the bin is compatible with your forklifts or cranes by checking for appropriate fork pockets or lifting lugs.

- Durability and Maintenance: Opt for bins made from durable materials that can withstand tough conditions. Regular maintenance will extend their lifespan.

Enhancing Workplace Safety with Self-Dumping Bins

To maximize safety, ensure that employees are properly trained in operating self-dumping bins. Conduct regular inspections to check for any wear or damage. Adhering to load limits and communicating clearly with team members helps prevent accidents.

The Future of Self-Dumping Bins

The future of self-dumping bins includes advancements in automation and sustainability. Automated bins could operate independently, using sensors to detect when they’re full and triggering the dumping process. Sustainable materials, such as recycled steel, will reduce environmental impact. Enhanced safety features, like automated locking mechanisms, will make these bins even more secure and stable.

Conclusion

Self-dumping bins are essential tools for efficient material handling and waste disposal. Whether you’re using them in warehouses or construction sites, these bins offer a reliable solution for managing waste and improving productivity.