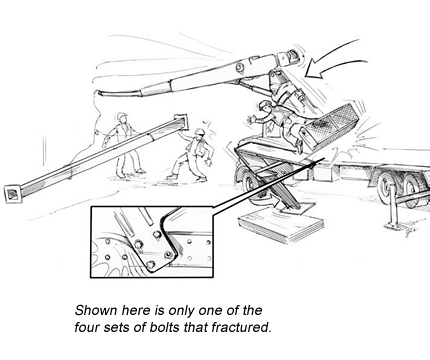

A crane was lifting a 360-kilogram (800-pound) steel I-beam into position for a house under construction. Two workers were waiting to guide the beam onto two steel columns when the crane suddenly came off the truck’s chassis. The crane’s boom, along with the steel beam, fell onto the floor of the house. The two workers were both knocked over. One died from his injuries, and the other sustained serious injuries. The crane operator was also injured when he fell or jumped from the operator’s platform.

The bolts that attached the crane to the truck frame had fractured.

Safe work practices:

* Use an appropriate method of inspection and testing to ensure the integrity of the bolts that attach the crane to the truck frame. The bolts could also be replaced on a regular basis.

* Ensure that mobile cranes are thoroughly inspected at least once every 12 months and certified by a professional engineer. These inspections must ensure that cranes meet the manufacturer’s specifications and all other applicable design and safety standards. Inspections must also be conducted periodically throughout the 12-month period as necessary and as specified by the manufacturer to ensure that all crane components function as intended.

* Maintain mobile cranes as specified by the manufacturer or a professional engineer. Maintenance and repair must be done by—or under the direct supervision of—a qualified person.

* Ensure that operators inspect mobile cranes—including control and safety devices—before each work shift. Any defects must be reported right away to a supervisor. Crane operators must also keep records of inspections and maintenance.

* Ensure that crane operators have access to the manufacturer’s manual or a professional engineer’s instructions for the crane.

Source:

http://www2.worksafebc.com/i/posters/2011/ha2011-02_mobile_crane.html